Polariscope Stress Analysis

The Role of a Polariscope in Stress Analysis for Transparent Materials

For transparent materials such as glass and plastic, strain refers to the forces inherent in the material. These forces can impact the performance characteristics of the material, and in a production environment, should be monitored to ensure the materials are being producted within spec. In particular, strain can impact a material in a number of ways:

- Strength: Stressed materials are more prone to cracking or breaking under pressure.

- Performance: Internal stress can affect optical clarity, electrical properties, and dimensional stability.

- Durability: Over time, stress can lead to crazing (fine cracks) or spontaneous breakage.

Image Credit: https://luceo.co.jp/en/wp-content/uploads/2022/04/Polariscope_leaflet_202202_E.pdf

Polariscope: Unveiling the Hidden Threat

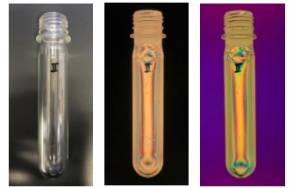

A polariscope is a valuable tool that utilizes polarized light to visualize internal stress patterns within transparent materials. As light of different polarizations pass through a stressed area, the impact of strain affects the polarized light in different manners, leading to an optical retardation that is reflected by the stress in the material. By performing 2D retardation imaging, engineers may elucidate a number of important features in the material, such as:

- Identify Stress Points: Precisely locate areas of high stress.

- Quantify Stress Levels: Measure the severity of internal stress for quality control purposes.

- Optimize Production Processes: Identify areas for improvement in manufacturing to minimize stress and ensure consistent product quality.

Polariscope: Beyond the Naked Eye

The polariscope’s function hinges on a scientific principle called birefringence, a property of certain materials where light rays are split into different polarizations upon entering the material. When a material is under stress, its refractive index changes, causing this splitting to occur. In the polariscope. this change manifests as an optical retardation that is measurements by the system – this can be rendered as a multicolor image, revealing valuable insights into the material’s structural integrity.

By visualizing stress images, polariscope stress analysis empowers manufacturers to:

- Identify Potential Weak Points: Detect weak spots in preforms before production begins, preventing costly rework or product failures.

- Optimize Molding Processes: Refine molding processes to minimize stress during preform creation, leading to more consistent and reliable production runs.

- Ensure Quality Standards: Guarantee final products meet stringent quality standards for strength and durability, ultimately enhancing customer satisfaction and brand reputation.

The polariscope, therefore, serves as a critical tool in manufacturing transparent components, safeguarding product quality and ensuring the success of the entire production process.

Considering incorporating polariscope stress analysis into your quality control procedures? Contact us today to discuss your specific needs!

Related Products:

LSM-9002LE: Strain measurement in the visible across a 175×175 mm area

LSM-9002S: Strain measurement in the visible with a variable field of view for 10-10 to 60×60 mm

LSM-9001NIR: Near-IR system to measure strain in semiconductors.

LSM-9100WNIR: Near-IR system to measure strain in resins and other plastics.