MICROMANIPULATOR IN TRACE ANALYSIS

Updated On December 5 2019

Micro Support Micromanipulator for Separation of Paint Layers in Trace Analysis.

Background

The Mississippi State Crime Lab (Jackson, MS) handles a wide range of trace analysis cases. One particular interest for the crime lab was the ability of the Micro Support Axis Pro micromanipulator to separate paint layers in a multi-layer paint sample.

Steve’s Solutions: Micro Support Micromanipulator for Separation of Paint Layers in Trace Analysis

Updated On December 9 2019

Background

The Micro Support Axis Pro micromanipulator provides strong capabilities for separate paint layers in a multi-layer paint sample.

Forensic labs obtain need to separate paint layers for trace analysis. Recently, a state crime lab requested a demonstration on the separation of a paint layer from a “difficult” sample.

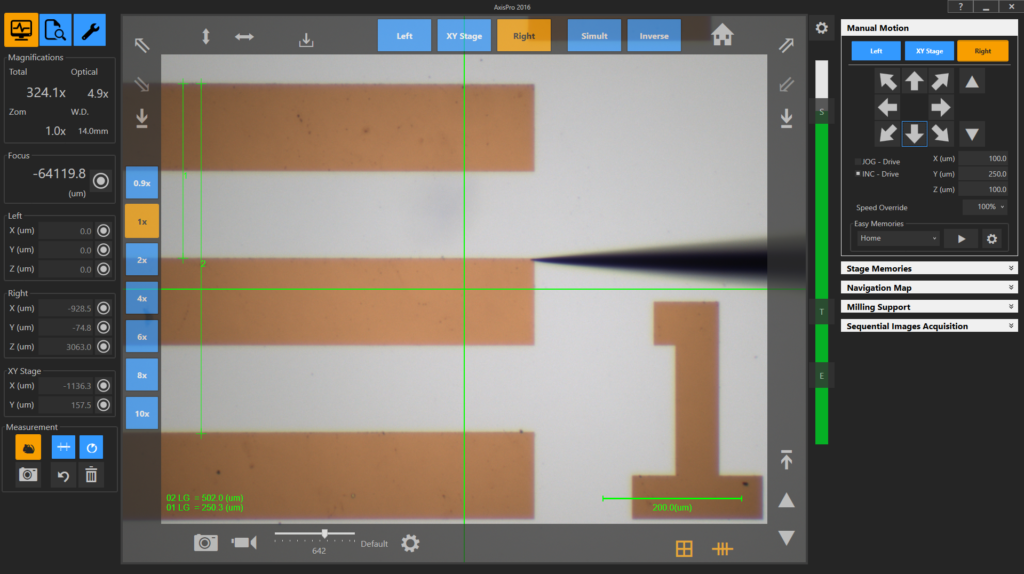

Equipment

The Micro Support Axis Pro micromanipulator is a zoom microscope that includes a motorized XYZ stage and two motorized arms with XYZ motorized control. All motion is accomplished through precise stepper motors with 0.1 μm/step resolution. Motion of the stage and arms is accomplished through a software interface that shows the visual image. The computer mouse controls the motion and the software/controllers vary the degree of movement as a function of the zoom of the video image – if the image under view represents a large field of view, mouse motion will cause the stage/arm to move a relatively large distance. If the field of view is relatively small (accomplished by operation at a high magnification), then mouse motion will cause a relatively small degree of movement in the stage or arm.

Some of the tools that are available for use with the Micro Support Axis Pro include:

• Probes (tungsten, tungsten carbide)

• Knives (stainless steel, ruby)

• Scrapers

• Micro-tweezers

• Vacuum absorption tool (for picking up grains)

• Sampling probe (solid glass probe for retrieval of FIB foils)

• Micro-pipette (for use with vacuum absorption tool and liquid pickup/delivery – future application)

• Super-fine Pitch Rotator (to rotate probe in the axis of the probe – useful for occasions when the particle is located on top of the probe)

• Electrode holders (for electrical measurements)

• Micro-welding kit

Samples

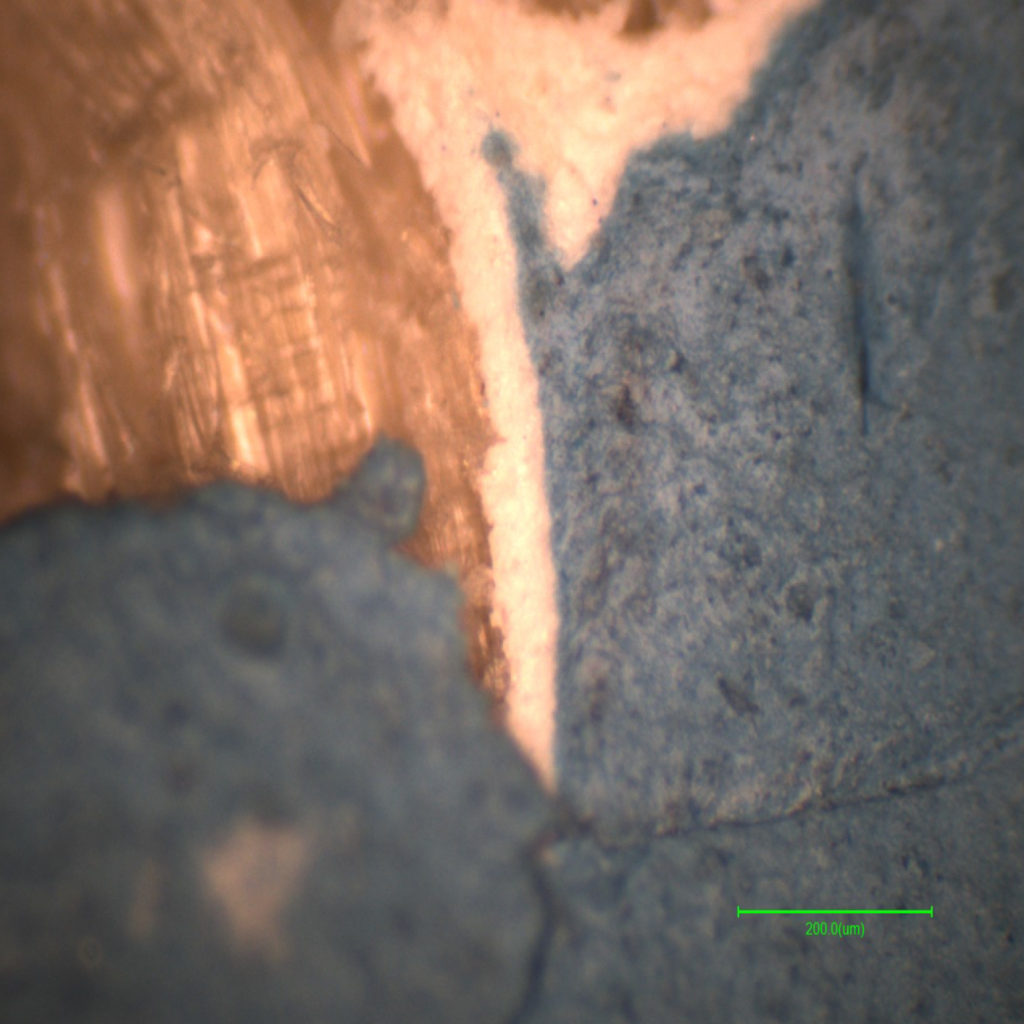

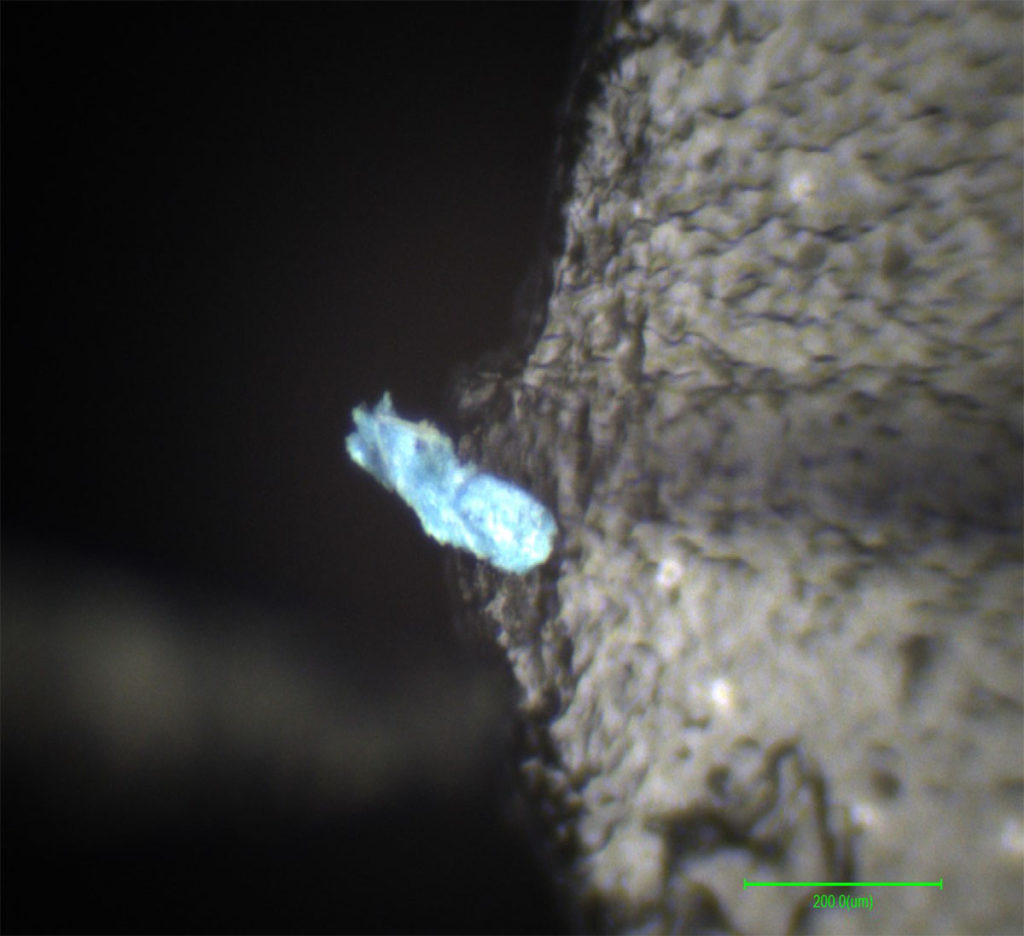

The primary interest for the crime lab was related to the separation of paint layers in a multilayer paint chip. Lab personnel selected a latex paint sample that included a blue layer that they wanted to have separated from the rest of the paint sample. Ideally, they wanted to separate a chip and transport it to the edge of a piece of scotch tape mounted in a sample holder. Placement of a paint sample in this location is valuable for subsequent FTIR analysis.

The sample was immobilized on the stage surface using double-coated carbon-conductive tabs which have adhesive properties on both sides.

The image of the paint chip sample was taken with a normal field of view as shown below. A 10×10 navigation map image was also used to locate a region of interest.

The image below shows the target for the paint chip sample to be separated (a piece of tape affixed on a mount).

Video image of paint chip sample

Initially, separation of the paint chip layers was attempted using a horizontal tungsten carbide tool. As shown in the video below, separation was not possible as applying pressure onto the sample caused the sample to move on the stage. This video shows that the sample is quite elastomeric and that the use of the tungsten carbide tool in this manner will not provide for separation.

Video File: https://youtu.be/LG_y3xoCJ0w

Paint Chip Layer Separation with Micro Support Milling Pro Accessory

The difficulty in separating the blue layer led to an attempt using the Micro Support Milling Pro accessory for separation. This accessory induces a hypersonic vibration into the tool – this vibration often facilitates shaving off thin surface from many materials. As illustrated in the video below, this accessory provided good separation of the blue layer from the other coatings.

Video: https://youtu.be/GafBKuzCNKo

Automated Motion of Film Removal

All the steps taken above were performed with manual motion of the tools in use. The Axis Pro system also enables Automated Motion to remove a layer of material. Using this feature, the top layer of paint was removed using Automated Motion as shown in the video below. It appears that the sample was not fully flat so the amount removed increases as the tool moves down the sample.

Video: https://youtu.be/ivQjsOhRN2I

Use of Axis Pro Micromanipulator for Small Particle Isolation

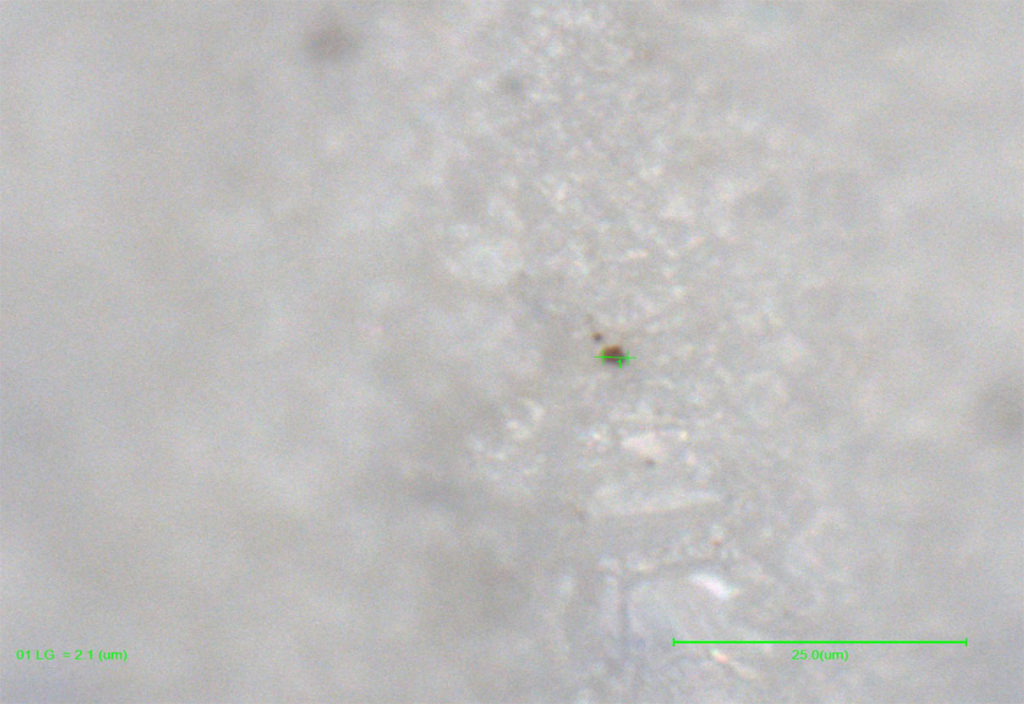

Although the main focus of this test was related to paint chip manipulation, a final test was also performed to assess the imaging capabilities of the Axis Pro system. At the maximum magnification, the Axis Pro system can provide magnifications that provide the ability to observe a particle that is 2 μm in size. This type of particle is routinely isolated by other Axis Pro customers and illustrates the potential for using the Micro Support Axis Pro micromanipulator for particle isolation.

Conclusions

The Micro Support Axis Pro with Milling Pro provides a powerful tool for paint layer separation, especially in situations where the paint layers are difficult to separate by other means. For criminalistic applications, there are a range of other applications where this technology may be applied for trace analysis.

Steve’s Solutions

To view the micromanipulator in action, visit the Steve’s Solutions article featuring this instrument.

For More information

Micro Support page

Micro Support Manufacturers Website

Contact Us Online Form

Phone: 916-897-2441

Email: [email protected]