Zircon dating is extensively used to estimate the age of a geological sample. An accurate measure of the geochronology requires zircon grains to be separated from larger mineral samples for measurement of the isotope ratios within a particular grain.

Traditionally, manual separation has been used – this technique works well for grains larger than 100 μm, while grains under this size are best separated using a micromanipulator. However, this process is slow and laborious, often taking weeks to prepare a single sample for analysis. The Micro Support Collection Pro automates this process so that grain separation can often be performed in an overnight run. This gets the analysis done quicker and allows for faster publication of results!

Manual Grain Separation

Manual separation of micro-grains can be performed using a number of different tools:

- Tungsten probe, for grains smaller than 20 μm: an electrostatic interaction occurs as the tungsten probe nears the grain, causing the grain to adhere to the probe, and allowing it to be separated.

- Vacuum absorption, for grains that are 20–500 μm in size: a micropipette with a diameter smaller than the grain is affixed to the motorized arm of a micromanipulator. The operator moves the pipette close to the grain, initiates a vacuum to provide suction thus attaching the grain to the tip of the micropipette. The micropipette tip is moved to the location at which the grain should be deposited, the vacuum is turned off and the grain is released.

- Micro-tweezers, for grains 20–500 μm in size: micro-tweezers are mounted onto one of the manipulator arms. The user positions the tweezers around the grain and closes them around the particle. After the grain is moved to the new location, the tweezers are opened and the grain is deposited onto the new surface. This approach is particularly useful for moving grains from an adhesive surface.

These techniques for manual separation have been the gold standard for zircon separation, mainly due to the lack of any other method for separation.

Automated Grain Separation

Micro Support offers the Collection Pro system as an automated zircon sorting and collection system using the Micro Support Axis Pro benchtop micromanipulator with advanced imaging technology system to rapidly and automatically perform zircon identification and separation.

The Collection Pro is available in two forms – a simplified zircon separation system that uses a robust image classification system and an advanced Collection Pro AI product that uses a powerful AI-based algorithm for superior classification of zircons for separation.

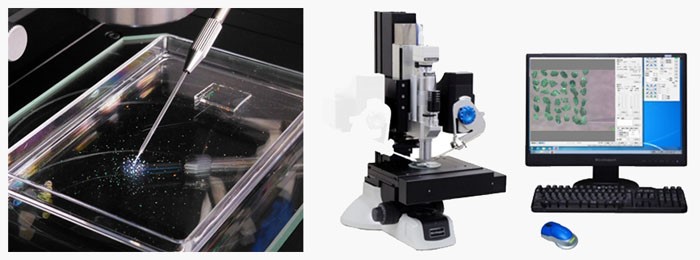

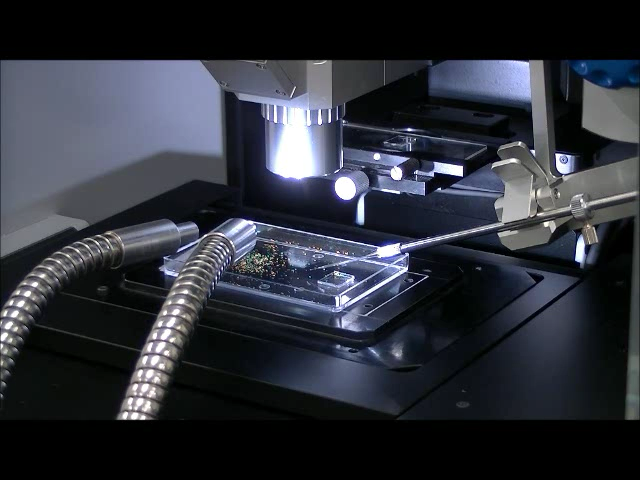

Figure 1 – Micro Support Collection Pro System.

Easy 4 step process to collect samples

There are four easy steps to performing a zircon grain separation.

- Automatic imaging and classification of grains in a mineral sample. Data on the size, shape, and color of each grain are automatically obtained

- Editing of results

- Collection set-up including selection of particles to separate

- Automatic collection

Micro Support offers the Collection Pro an automated micromanipulator system for zircon separation. (see Figure 1). The software provides image analysis and identifies grains based on shape, size and/or color.

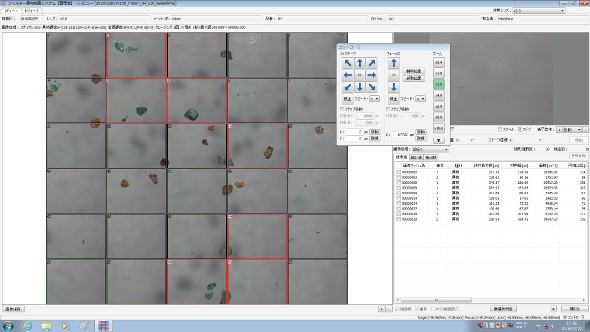

Using the automated XY stage, the micromanipulator generates a large image of the area of interest by tiling individual images. The user then selects some representative grains for separation.

Grain Identification

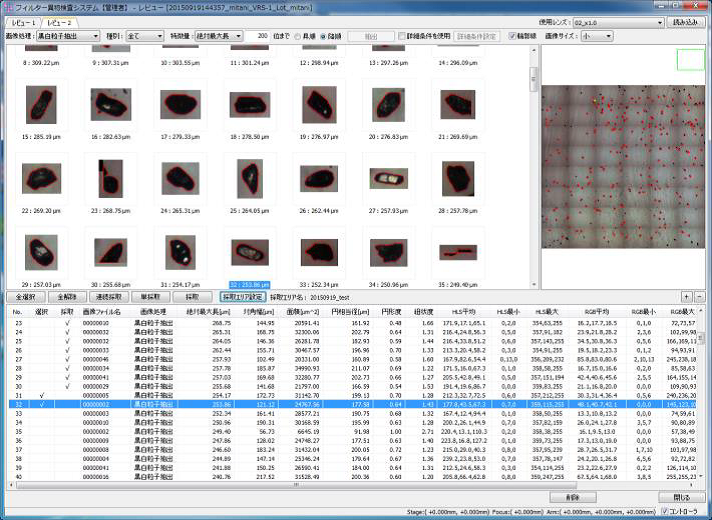

The Collection Pro software distinguishes the grains that should be separated from those that should remain with the bulk matrix based on the following criteria:

- Color: determined using hue, lightness, saturation or RGB standards

- Area and perimeter: area and perimeter are measured, without taking into account any voids or holes in the grain

- Diameter: diameter of a circle that is approximately the size of the grain

- Maximum length across the grain

- Maximum length/breadth: ratio of the maximum length divided by the breadth

- Circularity: degree to which the shape of the grain is approximated by a circle.

The user defines the types of grains to be separated, and the system automatically identifies grains in the image area to be separated (see Figures 2 and 3).

Figure 2 – Display of Collection Pro software illustrating tiled images and grains to be separated.

Figure 3 – Another view of Collection Pro software illustrating tiled images and grains to be separated.

Grain Separation

Once the grains for separation have been identified, there are two different modes that may be used.

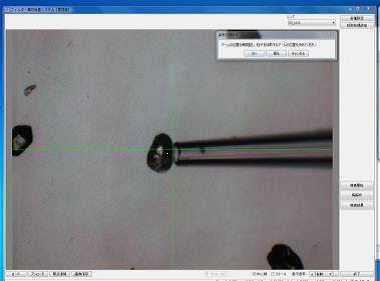

For grains larger than 50 microns a vacuum micropipette may be used. In this instance, the tip of a micropipette is brought up to the grain, a light vacuum is applied to pick up the particle, the particle is then transported to the target deposition region, the vacuum is turned off, and the grain is placed in position, ready for analysis. Figure 4 shows a grain held at the tip of a micropipette. A video of this transfer may be seen at this link: https://goo.gl/iAjooP.

Figure 4. Grain held at the tip of a micropipette as it is moved to the deposition region.

For grains smaller than 50 microns, the best mode of transfer is often the use of a tungsten probe. The probe is brought in proximity to the grain that will be separated. As it approaches the grain, electrostatic attraction brings the grain in contact with the probe, allowing the probe to be raised and the grain to be transferred to the deposition region. A video showing this mode of transfer may be seen below:

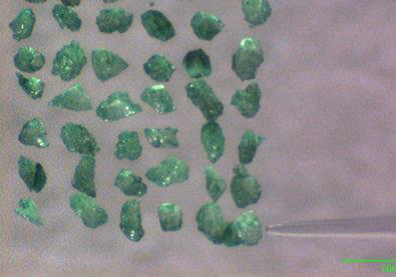

Each particle is deposited in the deposition area with a pattern that allows for easy analysis by external methods. A view of the deposition area may be seen in Figure 5.

Figure 5. View of separated particles in the deposition area.

Artificial Intelligence for Zircon Separation

The Collection Pro algorithm for zircon grain image recognition leverages an image analysis product that has been on the market for many years. Now, the Collection Pro AI can provide superior results to the standard algorithm as modeling of standard samples allows for a more robust identification and separation algorithm.

Conclusion

The Micro Support Axis Pro is a powerful tool for precise microsampling. The power and throughput of this system is increased significantly when combined with image analysis software and automated routines to separate zircon grains in geological samples. Recently, one of the Collection Pro customers separated more than 6000 grains in an overnight run with an accuracy of approximately 90%. This combination of a software-driven micromanipulator with image-recognition algorithms provides a powerful tool for the separation of micro-grains in mixed solid matrices.

Steve’s Solutions

To view the micromanipulator in action, visit the Steve’s Solutions article featuring this instrument.