Ex situ lift-out With a Benchtop Micromanipulator

Transmission Electron Microscopy (TEM) represents one of the most powerful super-microscopy techniques for material characterization. In order to obtain powerful images, it is critical to have a very thin section of material that allows for electron transmission through the sample.

Thin sections for TEM measurements are typically produced by Focused Ion Beam (FIB) techniques inside a Scanning Electron Microscope (SEM). These FIB foils are 100-200 nm thick and must be handled with great care for transfer to a TEM grid. This transfer (called lift-out) is often performed with a micromanipulator inside the SEM. These in situ systems are an industry standard and work well. However, the in situ FIB foil transfer can take up quite a bit of chamber time that could be used for other processes.

The Micro Support Axis Pro micromanipulator can transfer FIB foils to TEM grids outside (ex situ) the SEM chamber. The system includes a zoom microscope, a motorized XYZ stage, and two motorized arms. The arms can be configured with a wide range of tools including probes, knives, scrapers, and micro-tweezers which allows for sampling of many materials smaller than 10 μm.

The stage and both arms are precisely controlled by stepper motors through mouse control with a PC interface with movements of the stage and arm can be as small as 0.1 μm per step.

Overview and Examples of ex situ Lift-Out

A number of techniques may be employed for FIB-foil transfer. Some initial examples of these transfers in action may be seen in the video below:

Manual FIB-Foil Transfer

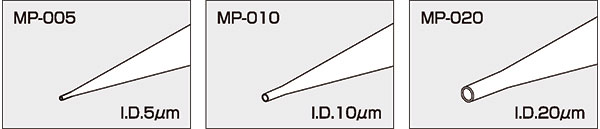

For ex situ lift-out, a solid glass probe (1-10 μm tip diameter) is used for transfer. A glass probe is positioned on one arm and approaches the FIB foil on the surface. The foil is held on to the glass probe through electrostatic adhesion and the probe is then moved to the TEM grid where the FIB foil is deposited.

Semi-automated solutions

Micro Support also offers a semi-automated solution for lift-out operations using using the Micro Support Vacuum Adsorption tool whereby a small vacuum is applied to a micropipette. For non-lift-out operations, this allows the system to pick up small grains and transfer them to another location.

For lift-out applications, a special micropipette with a 45-degree cut is used to approach the surface at normal incidence. The probe is then lowered and a gentle vacuum is applied to pick up the FIB foil. The probe is lifted up from the surface, and the probe tip is rotated out of the plane to allow for free motion to the TEM grid. The stage moves to the target region, the probe is lowered, and the probe is rotated so that the probe is at the surface. Finally, the vacuum is removed and the FIB foil is deposited in the target location.

Automated Lift-Out Solutions

This semi-automated lift-out procedure can be automated further through the Axis Pro’s ability to input coordinates from selected dual-beam SEMs. These coordinates direct the Axis Pro to the appropriate location for FIB foil lift-out. Using this approach, the Micro Support Axis Pro micromanipulator can automatically perform lift-out on FIB foils located throughout a full wafer.

Conclusions

The Micro Support Axis Pro Micromanipulator allows for ex situ lift-out through manual, semi-automated, and fully automated methods. These methods increase the performance of dual-beam SEMs so that chamber time can be focused on FIB foil generation while lift-out is performed as an ex situ operation.

Steve’s Solutions

To view the micromanipulator in action, visit the Steve’s Solutions article featuring this instrument.

For More information

Micro Support page

Micro Support Manufacturers Website

Contact Us Online Form

Phone: 916-897-2441

Email: info@Barnett-Technical.com