Technical

Methods for the Detection and Monitoring of Microplastics in the Environment

Wednesday, January 18, Webinar at 6:30 PM Pacific time [Register Here] Abstract: Microplastics have recently been…

Hot Disk Thermal Testing

We are happy to announce that Barnett Technical Services is now a distributor for Hot…

Anisotropic Thermal Conductivity and Diffusivity of Li-ion Batteries

Li-ion batteries represent many of the most critical areas of development in energy storage. The…

MobileGuard Gas Detection

Teco Peoples Gas hits the road in one of their new methane detection vehicles. These…

Installation Highlights

We are glad to share the news about the implementation of Barnett Technical Services installation…

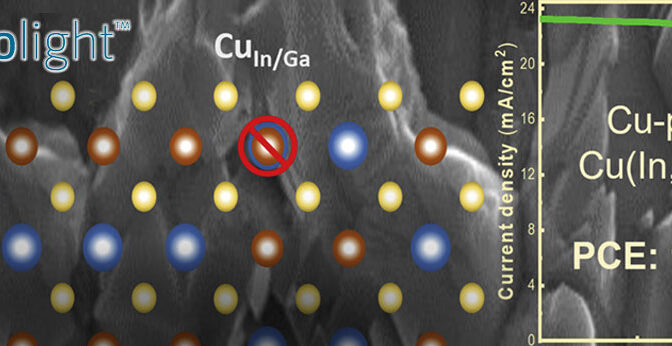

AttoLight’s CHRONOS Time-Resolved Cathodoluminescence for characterizing CIGS SOLAR CELL

Attolight's Chronos time-resolved cathodoluminescence tool was recently used to characterize an advanced Cu(In,Ga)S2 device that showed…

Quantum Diamond AFM

Quantum Diamond Atomic Force Microscope (QDAFM) is a quantum precision measurement instrument based on both…

NIKON LV MOD – ACHIEVE SUB-100 NM RESOLUTION ON THE NIKON LV SERIES

Nikon Metrology is partnering with LIG Nanowise to bring super-resolution microscopy using the LIG Nanowise microsphere…

Ramanomics: Quantification of Proteins, Nucleic Acids, & Lipids Inside Eukaryotic Cells

Molecular function in eukaryotic cells can be studied by quantifying proteins, nucleic acids, and lipids…