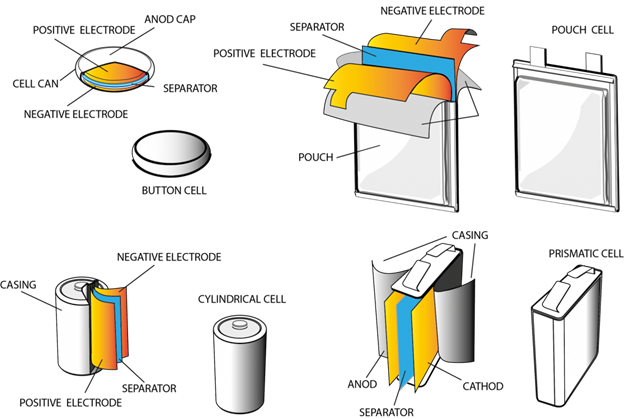

Li-ion batteries represent many of the most critical areas of development in energy storage. The appeal of these systems arise from their higher energy densities, longer life cycles (charge and discharge), and lighter weight compared to typical battery chemistries. These batteries have been developed into a number of common forms as shown in Figure 1.

Figure 1. Examples of 4 different shapes of Li-ion batteries

Li-ion batteries produce heat when operating – a high operating temperature (typically in excess of 55°C) can accelerate battery aging and shorten its lifespan. Therefore, an effective thermal management system (TMS) is needed to guarantee that the battery operates in the desired temperature range and to minimize any temperature difference from cell to cell.

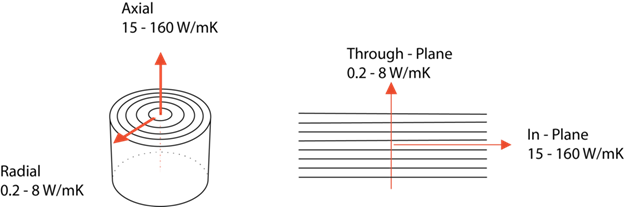

[To engineer a suitable TMS, the directional dependent thermal conductivity and thermal diffusivity of the battery cell must be determined. Hot Disk instruments provide a unique approach using the anisotropic module to swiftly and accurately measure these properties with a single transient.

Most recent Hot Disk cases involving battery technology have been related to Li-ion batteries arranged in pouch cells. With this assembly, Hot Disk has regularly observed much higher thermal conductivity in both in-plane and through-plane directions with values of up to 160 W/mK in-plane, and up to 8 W/mK through-plane. Manufacturers have worked on improving the thermal conductivity of enhanced Li-ion battery structures using the Hot Disk technique to analyze the thermal properties of these batteries.1-3

Figure 2. Anisotropic structures inside battery cells.

In Table 1, measurements on pouch cells that are currently produced by different manufacturers of electric vehicles are shown. It should be noted that the through-plane, mechanical pressure, surface roughness, and/or other chemical solutions, will strongly influence the thermal contact resistance between layers, thereby influencing the effective thermal conductivity in the through-plane direction.

Table 1. Thermal transport properties of different pouch cells measured by the Hot Disk anisotropic module, using Hot Disk sensor 4922, heating power 1 W, measurement time 10 – 20 s.

| Dimension [l x w x h, mm3] |

pCp [MJ/m3K] |

Through-plane λ [W/mK] |

Through-plane κ [mm2/s] |

In-plane λ [W/mK] |

In-plane κ [mm2/s] |

|---|---|---|---|---|---|

| 212 x 113 x 9 | 2.36 | 1.0279 | 0.4356 | 16.394 | 6.9468 |

| 69 x 47 x 4.65 | 2.71 | 1.4794 | 0.5465 | 17.844 | 6.5918 |

| 325 x 100 x 12 | 2.55 | 1.5142 | 0.5938 | 17.826 | 6.9905 |

| 273 x 97 x 11 | 2.61 | 1.0186 | 0.3903 | 21.710 | 8.3189 |

| 144 x 80 x 12 | 2.51 | 0.8857 | 0.3529 | 18.889 | 7.5253 |

| 120 x 105 x 11 | 2.54 | 1.4467 | 0.5696 | 20.060 | 7.8976 |

| 120 x 105 x 9.4 | 2.68 | 1.3121 | 0.4896 | 18.386 | 6.8313 |

| 270 x 97 x 11 | 2.44 | 1.5852 | 0.6497 | 16.837 | 6.9003 |

| 313 x 101 x 7.3 | 2.41 | 0.6615 | 0.2745 | 40.685 | 16.882 |

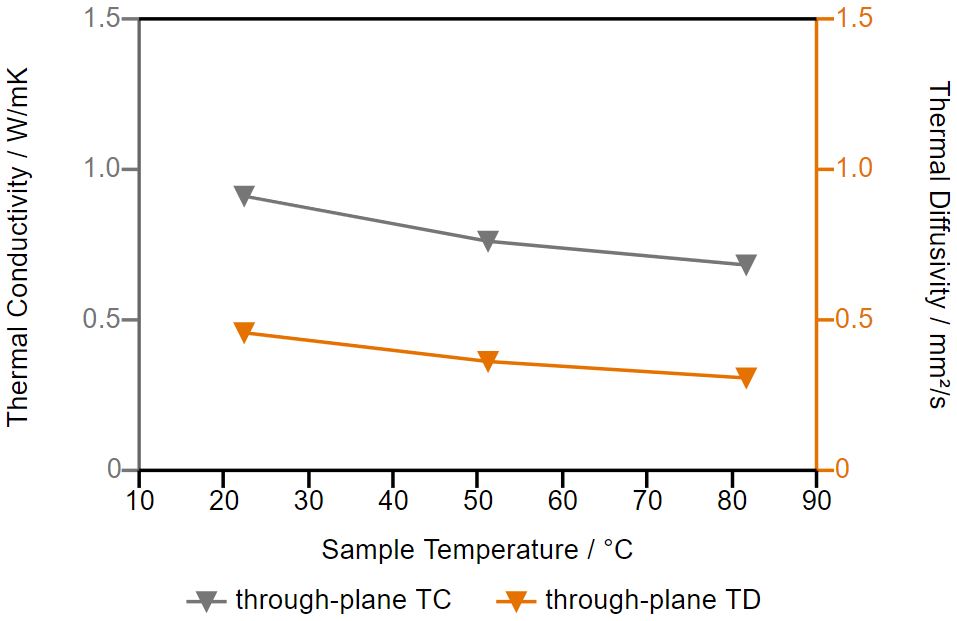

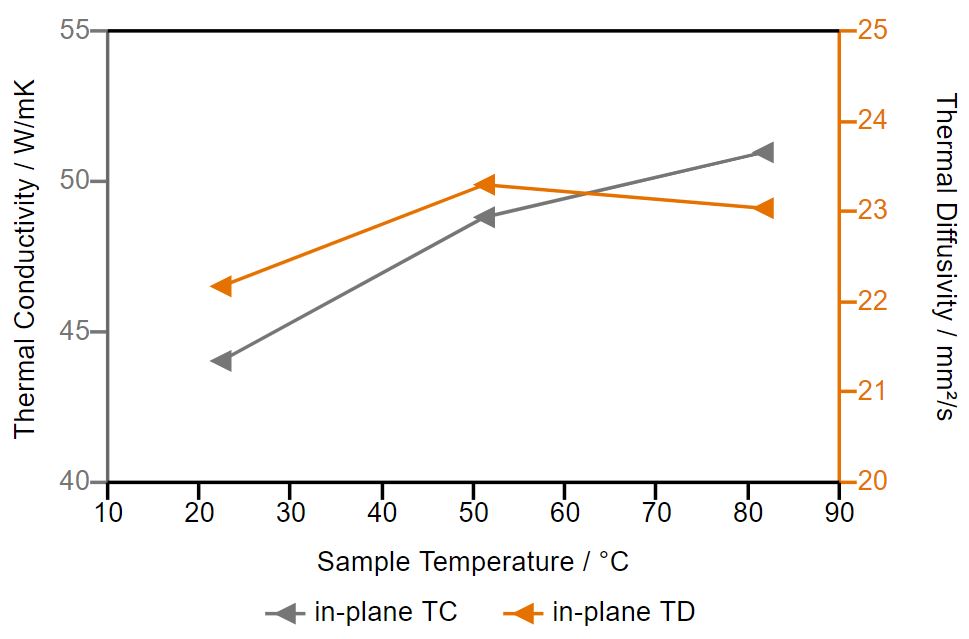

Some customers also were interested in the measurements of pouch cells at different temperatures. Figure 3 and 4 reveal the relationship of the thermal transport properties of one particular pouch cell as a function of from room temperature (RT) to 80 °C measured by the Hot Disk anisotropic module.

Figure 3. Through-plane thermal conductivity (left y-axis, in grey) and thermal diffusivity (right y-axis, in orange) of one particular pouch cell under test as a function of the sample temperature.

Figure 4. In-plane thermal conductivity (left y-axis, in grey) and thermal diffusivity (right y-axis, in orange) of one particular pouch cell under test as a function of the sample temperature.

Conclusions

Hot Disk instruments with the anisotropic measurement module provide an excellent tool for the development of Li-ion batteries – especially pouch cells. Hot Disk can provide a range of customized measurement geometries. Please contact us to discuss the potential for performing these measurements further.

The work described here was adapted from a more in-depth Hot Disk technical document found here.

References:

- B. Koo, P. Goli, A. Sumant, P. Ceilia, T. Rajh, C. S. Johnson, A. A. Balandin, E. V. Shevchenko, Toward Lithium Ion Batteries with Enhanced Thermal Conductivity. American Chemistry Society (ACS) Nano. 8(7): 7202–7207 (2014).

- P. Goli, S. Legedza, A. Dhar, R. Salgado, J. Renteria, A. A. Balandin, Graphene-enhanced hybrid phase change materials for thermal management of Li-ion batteries. Journal of Power Sources 248 37-43 (2014).

- Y. Xie, J. Tang, S. Shi, Y. Xing, H. Wu, Z. Hu, D. Wen, Experimental and numerical investigation on integrated thermal management for lithium-ion battery pack with composite phase change materials, Energy Conversion and Management 154 562-575 (2017).

For More information

BTS Hot Disk page

Hot Disk Website

Contact Us Online Form

Phone: 916-897-2441

Email: [email protected]