Strain Measurement in Microlenses Using an Automated Polariscope

Microlenses are polymer or glass lenses used in a wide range of products, including mobile phone cameras, LED systems, and solar cells. These lenses require high image clarity and optical throughput.

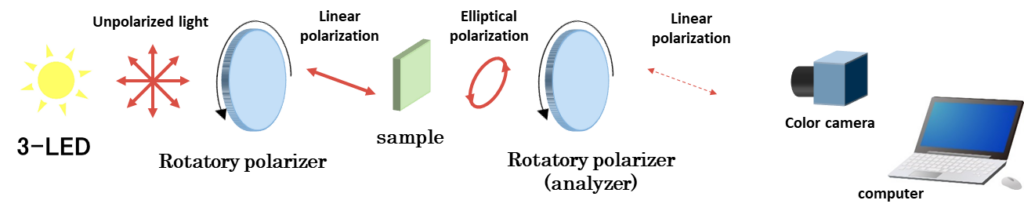

Robust microlens quality control includes an assessment of residual stress throughout the lens. Retardation measurements to assess stress in transparent optics is measured as the phase shift between the polarized component of light along the fast axis compared to that along the slow axis. Generally, retardations are larger in areas where there is greater stress on the optic.

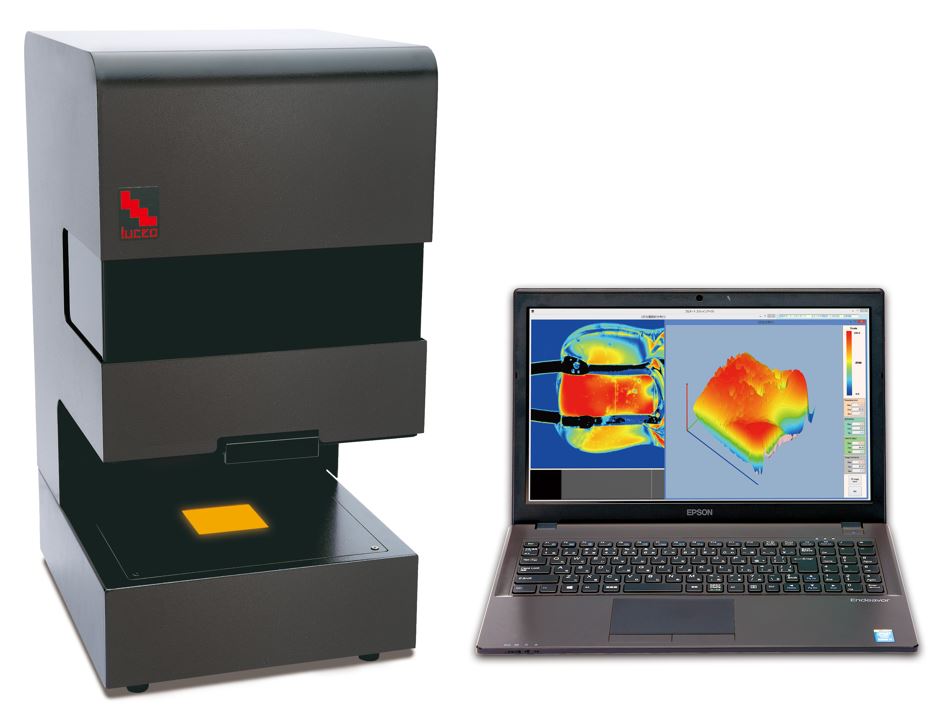

The Luceo LSM-9100S is an automated polariscope that provides precise retardation measurements with image resolutions as small as 10 microns per pixel. Polarized source light is passed through a transmitting optical material and then passed through an analyzing polarizer and onto a detector. Rotation of the analyzing polarizer through a range of angles allows for calculation of the retardation at different areas of the optical component being measured.

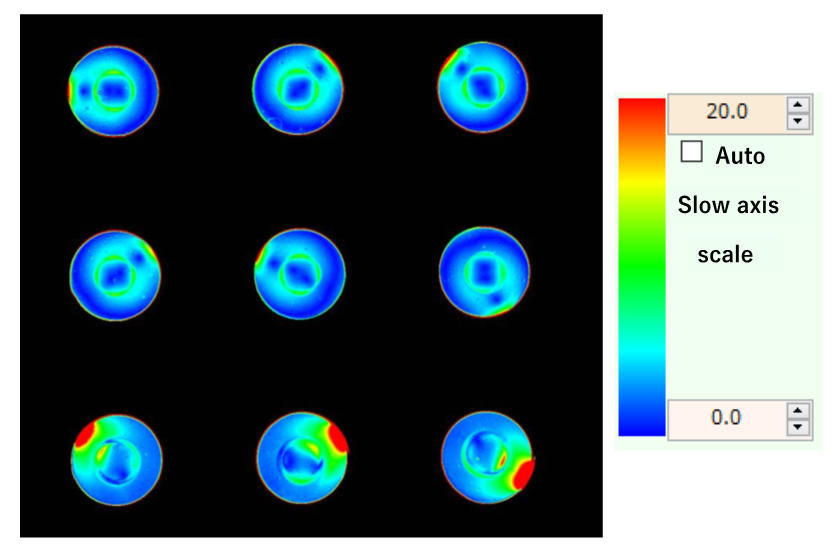

Microlens Measurements

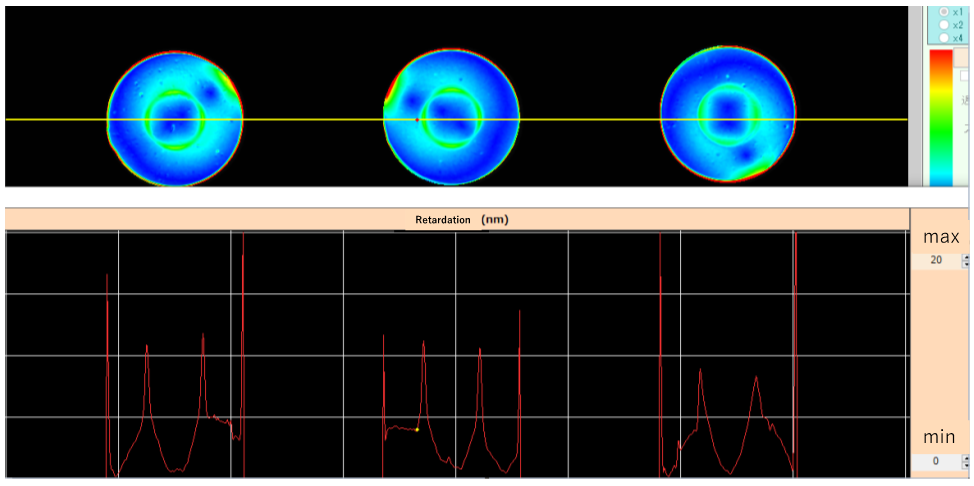

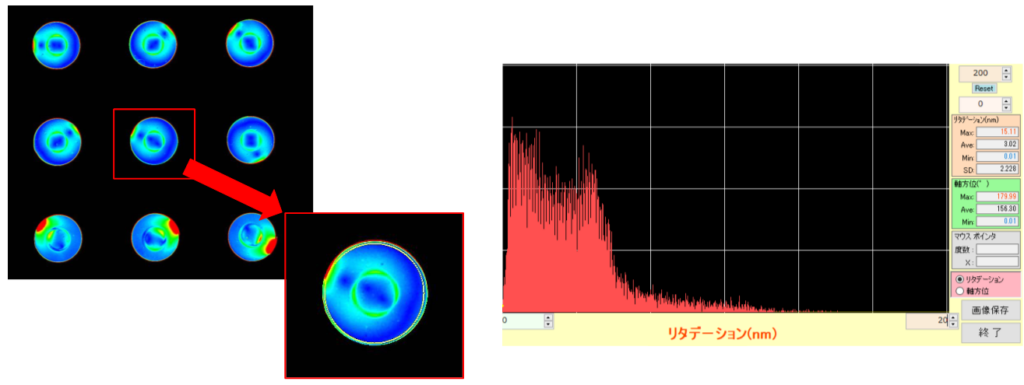

A 2-D array of microlenses (4 mm diameter) was measured with the Luceo LSM-9001S. Measurements took 30 seconds and a typical retardation image is shown below. A color scale is provided that shows the retardation values between 0 and 20 nm. Areas of highest stress (above 20 nm) are clearly shown in red and can be used to reject an out-of-spec microlens.

A plot of retardation across each lens can also be generated to understand the stress in different regions across the lens. This is often used in both an R&D and Production settings to understand the manufacturing process.

A histogram of retardation values through a single lens is also available to

understand the stress throughout each microlens.

Conclusions

Stress in microlenses can be easily evaluated using the Luceo LSM-9001S polariscope. A wide range of diagnostic images and plots are available and measurements are quick and simple for the routine operator. Information from retardation images may be used in both an R&D and Process Control setting.

For More information

Steve’s Solutions

To view Polarizers in action, visit the Steve’s Solutions articles featuring these instruments.

For More information

https://www.luceo.jp/Luceo Manufacturer Website.

Contact Us Online Form

Phone: 916-897-2441

Email: info@Barnett-Technical.com