Evaluation of Drummond Scientific Nanoject III Programmable Nanoliter Injector for Liquid Transfer with the Micro Support Axis Pro Micromanipulator.

Background

Micro Support manufactures the Micro Support Axis Pro micromanipulator for precise microsampling. A number of customers have requested the ability to precisely pick up or deposit a known volume of liquid onto a surface – a capability that is currently not available with the Micro Support Axis Pro system.

The Nanoject III Programmable Nanoliter Injector from Drummond Scientific allows for the injection of volumes as small as 0.6 nanoliters into or onto a material. The system is controlled by a motorized system where oil is drawn into a capillary, then the sample to be injected is drawn into the capillary. Deposition (volume, speed, etc.) is specified on the touchpad that accompanies the system.

Mounting of Dispenser

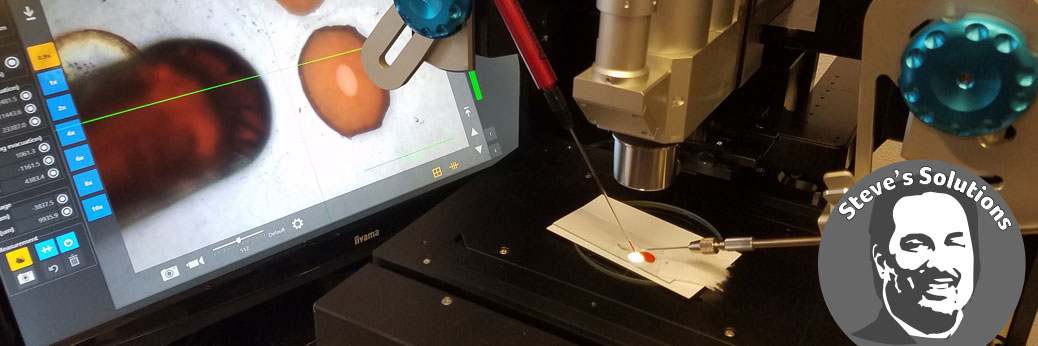

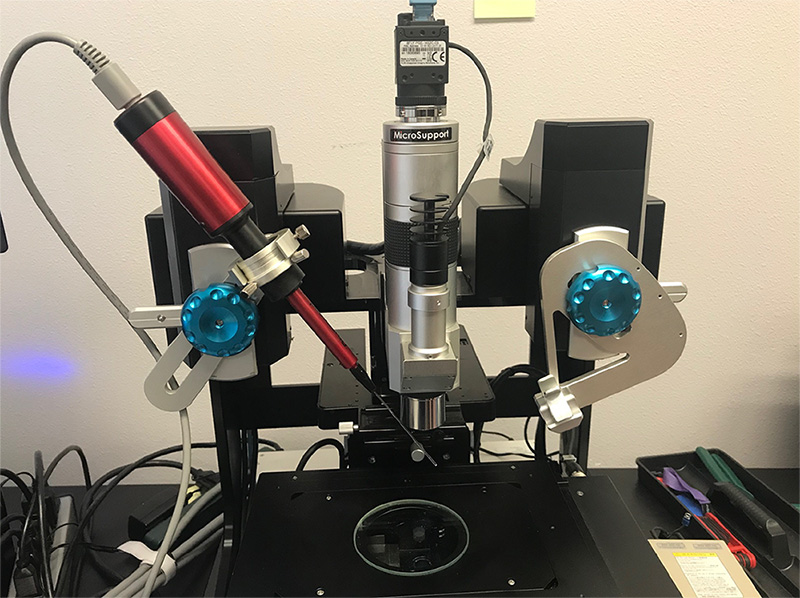

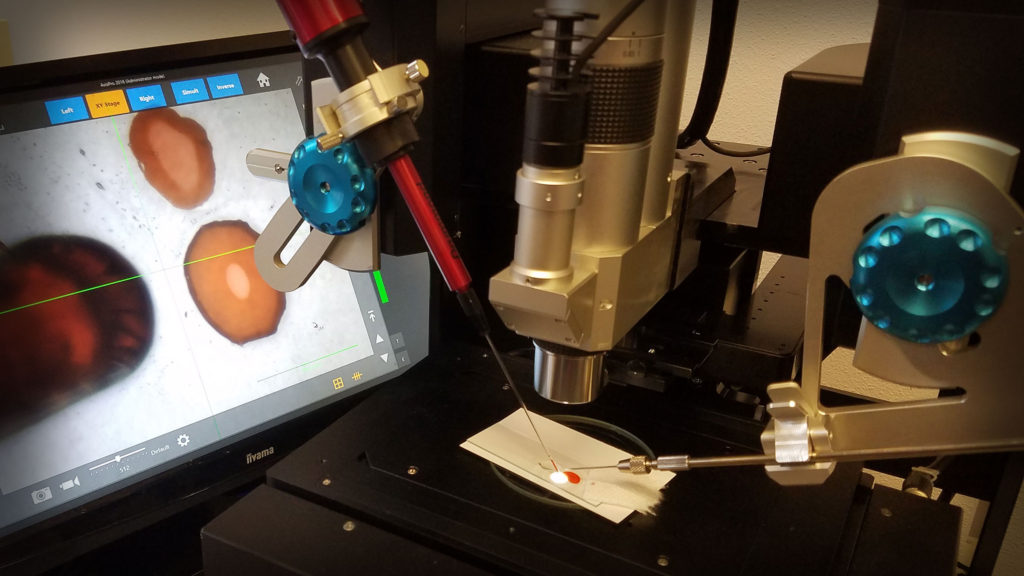

One aspect of this test involved mounting of the dispenser unit onto the Axis Pro. A universal arm was used in order to provide a high angle of approach to the sample and the Axis Pro was configured with a 1.5X objective to provide the longest working distance possible. An old Milling Pro mount was modified with a collar to hold the dispenser in place. An image of the setup may be seen here:

Capillary Size

The inner diameter of the capillary on the Nanoject III was approximately 750 μm in diameter.

Test samples

Two test samples were evaluated: a hydrocarbon oil and an aqueous solution with red food coloring. Deposition onto four surfaces was evaluated:

• Glass slide

• Metal (stainless steel)

• Polymer (packing tape – polyethylene or polypropylene)

• Paper

Procedure

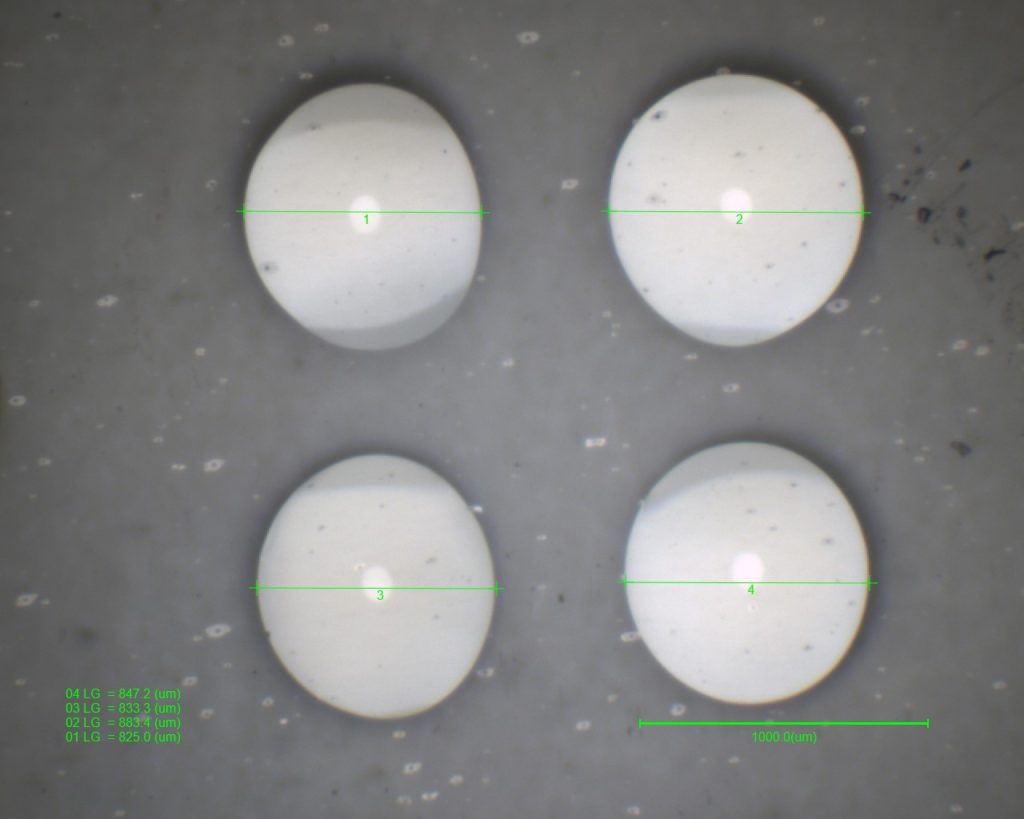

For each type of sample, oil was drawn into the capillary as a mediating fluid followed by the test sample. Where possible, depositions of 30, 50, and 100 μL were performed as a series of 10 μL aliquots (i.e., 100 μL was deposited with ten sequential 10 μL depositions). The diameter of the spot deposited was noted to provide some indication of spreading onto the surface. The images below illustrated how some spots the well-formed spots on the surface.

Hydrocarbon oil on polymer

A video showing the deposition of rows of 100 μL, 50 μL, and 30 μL of the aqueous solution may be seen here:

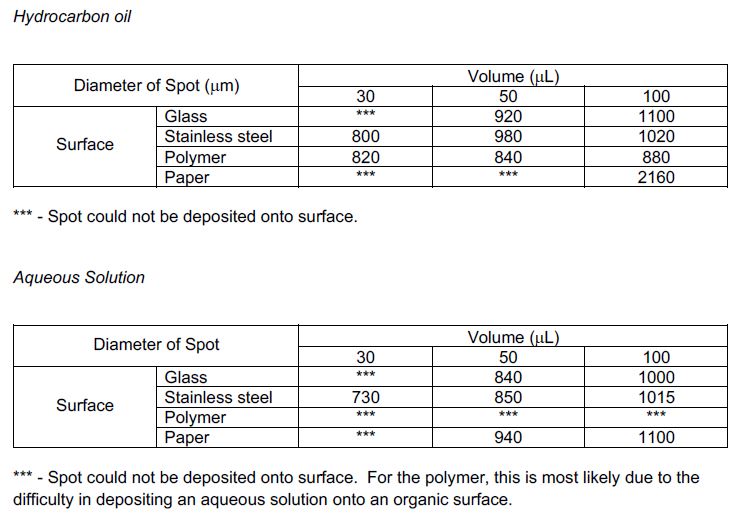

For the two liquids being deposited onto different surfaces, the resulting spot diameters were:

Picking up Liquid Samples

The Nanoject III is not designed for precisely picking up liquids. Given the desire of Micro Support customers to have this capability, an attempt to quantify this ability was made. This could be accomplished by rapidly hitting the “Fill/Stop” button on the control unit. This volume was then redeposited onto a surface to determine the approximate volume that was drawn in. Using this procedure, the volume drawn into the capillary was approximately 120 μL.

Summary

This work illustrates the potential of combining the Drummond Scientific Nanoject III Programmable Nanoliter Injector with the Micro Support Axis Pro benchtop micromanipulator for the specific delivery and picking up of small volumes of liquids in precise locations. Further developments will likely lead to improved performance of this combination of tools for liquid

handling.

About Drummond Scientific

Drummond Scientific supplies the best, most precise and innovative equipment to professionals in the bio and life sciences professions. Beginning with an innovative breakthrough in 1976 when we introduced the first Pipet-Aid pipette controller, we began blazing a trail and changed

pipetting in the laboratory forever. We continued to design and manufacture high-quality products that solidified our place as an industry leader. Company web site: https://www.drummondsci.com

About Barnett Technical Services

Barnett Technical Services distributes products for material characterization and manipulation. Our products typically emphasize the use of spectroscopy and/or microscopy.

About the Micro Support Axis Pro micro manipulator

Micro Support specializes in the development, design, manufacture, sales and maintenance of micro-sampling machinery used for analysis, as well as in the accessories used with them.

Steve’s Solutions

To view the micromanipulator in action, visit the Steve’s Solutions article featuring this instrument.

For More information

Micro Support page

Micro Support Manufacturers Website

Contact Us Online Form

Phone: 916-897-2441

Email: [email protected]