Barnett Technical Services

Distributors of microscopy and spectroscopy products for chemical

and materials analysis

Distributors of microscopy and spectroscopy products for chemical

and materials analysis

Distributors of microscopy and spectroscopy products for chemical

and materials analysis

Distributors of microscopy and spectroscopy products for chemical

and materials analysis

We have a broad range of applications including the fields below. If you do not see your application or have additional questions, please contact us.

Conferences November 1, 2023

Visit us at the 2023 Glass Problems ConferenceNov 6-8, Columbus, OH – Booth 103! Surface…

Conferences September 11, 2023

Please join us in Pasadena California, on October 30th to November 4, for ISTFA 2023.…

Conferences June 20, 2023

We are very excited to be attending Materials Research Society Fall Meeting, November 26 –…

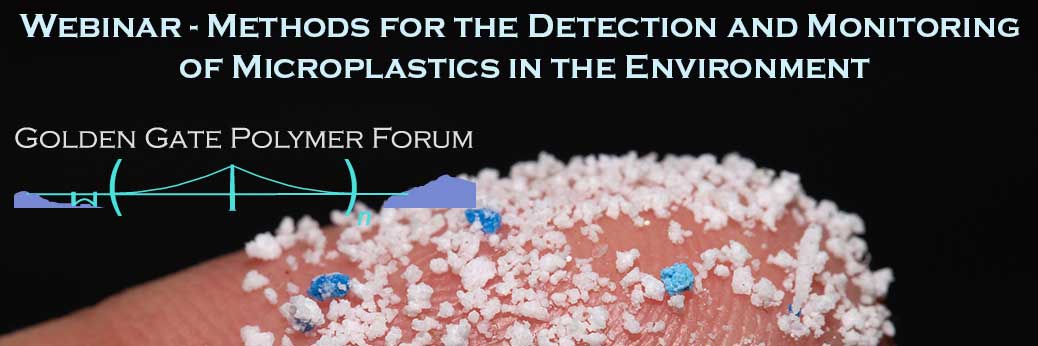

Technical June 9, 2023

Wednesday, January 18, Webinar at 6:30 PM Pacific time [Register Here] Abstract: Microplastics have recently been…

Technical May 22, 2023

We are happy to announce that Barnett Technical Services is now a distributor for Hot…

Conferences May 1, 2023

We are very excited to be attending GCC 2023 in Galveston Texas. Please visit us…

Conferences April 18, 2023

We are very excited to be attending SciX 2023 in Sparks, NV. Come visit us…

Conferences, News April 10, 2023

We are very excited to be attending Materials Research Society Spring Meeting, April 10-14, 2023,…

Conferences March 23, 2023

We are very excited to be attending Microscopy & Microanalysis 2023 meeting in Minneapolis MN, July…

Conferences December 15, 2022

Barnett Technical Services will be working with LUCEO in booth #4675 at Photonics West 2023,…

We had the first North American Micro Support Users Meeting…

December 15, 2022

December 15, 2022Barnett Technical Services will be working with LUCEO in booth…

March 21, 2022

March 21, 2022We are very excited to be attending Materials Research Society…

November 1, 2017

November 1, 2017We are very excited to be attending Materials Research Society…

December 4, 2019

December 4, 2019We have been following the outstanding work of Dr. Pangala…

September 2, 2020

September 2, 2020The spread of COVID-19 has led to great changes in…

November 1, 2023

November 1, 2023Visit us at the 2023 Glass Problems ConferenceNov 6-8, Columbus,…

February 10, 2020

February 10, 2020